- Home

- Custom Pile Hammer

Jinyi Sanchang has over ten years of experience in vibratory hammer manufacturing. We can provide custom hydraulic vibratory hammers for construction contractors, excavator refitting factories, and construction machinery manufacturers. We employ our own highly talented R&D team and professional production team allowing us to produce the most suitable vibratory hammer according to the piling type, construction technology, project requirements, construction site conditions, and blueprints. Our team can provide you with customization whether you are looking for an excavator mounted pile driving hammer, pile driving rig hydraulic pile hammer, or hydraulic power pack driving vibrator hammer.

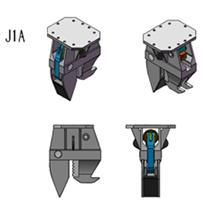

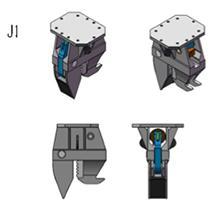

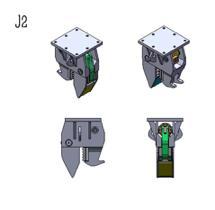

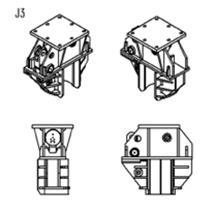

These are five kinds of grippers we can provide and they can be used for clamping of sheet pile and circular piles. Besides, we can also provide custom grippers according to your requirements.

- Material and parts purchasing

- Most raw materials are purchased from factories nearby so that the transportation cost can be saved and the production efficiency can be ensured. The structural components of the vibratory hammer are all made of steel with high intensity which features high fatigue resistance and large loading capability. All the other parts are products from international famous brands such as a motor from Parker, manifolds of hydraulic control system from SUN and electronic parts and components from Omron which feature good stability and reliable quality.

- Manufacturing and processing

- After inspection, all qualified raw materials will be put into production. The materials will be processed into precise components via CNC production line. The welding will be carried out by JQ.CE71T-1 flux cored wire. Finally, annealing is adopted to increase the intensity.

- The machining finished parts will be strictly tested based on factors such as hardness, tensile strength, crack magnetic particle tests, impregnation techniques and magnetic particles for crack detection, ultrasonic inspection, size, sealing performance and painting thickness. Only qualified parts will be used in assembly. The assembling finished vibratory hammer will be painted integrally. And will finally be inspected and put into the warehouse.

- Simulation experiment

- All the assembling finished vibratory hammer should pass simulation experiment before shipment. The speed, amplitude and temperature of the vibratory hammer should be tested. And only qualified products can be delivered to our customers.

- How to customize

- Simply tell us the specific construction conditions of your project such as pile type, site condition, piling method, environmental requirements, etc. You should also submit a geological report. If the vibratory hammer needs to be mounted on the excavator, tell us the tonnage and type of excavator you will be using. After examining your specific requirements, we can provide you with the most suitable custom vibratory hammer for you.

Wuxi Jinyi Sanchang Machinery Co., Ltd.

Add.: No.572, Xi Da Road, Xin Wu District, Wuxi City, Jiangsu Province

Fax: +86-510-88553925